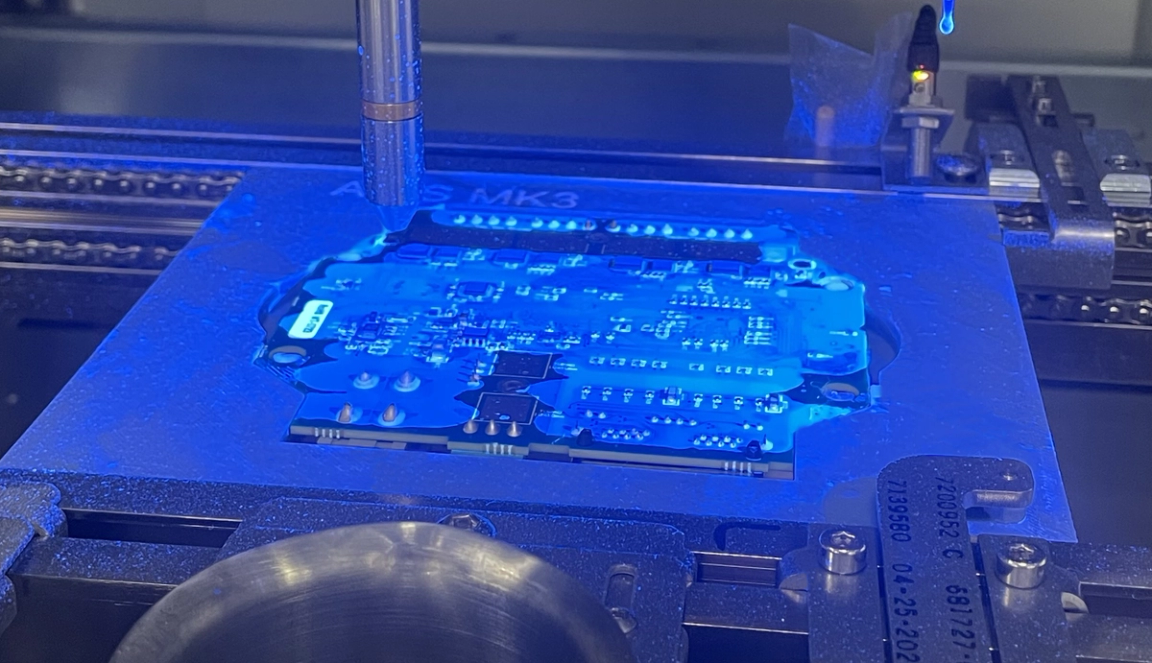

What is Conformal Coating?

Conformal Coating is a protective layer applied to electronic equipment, typically printed circuit boards (PCBs), to enhance their durability by protecting them from airborne moisture and dust or other adverse environmental factors.

Conformal Coating is available as an option on all PixLite® Mk3 devices and selected Classic PixLite® Mk2 devices.

What are the benefits of Conformal Coating?

1. Greater Protection Against Corrosion

Conformal Coatings create a barrier that shields electronic components from airborne moisture, dust, dirt, and other contaminants.

This helps prevent short circuits, corrosion, and other damage.

2. Increased Reliability and Product Life

By protecting sensitive electronic components from environmental factors, Conformal Coatings improve the overall reliability and lifespan of electronic devices, reducing the risk of premature failure.

3. Vibration Damping

Conformal Coating helps to stabilise components by acting in a manner similar to a glue, reducing the impact of vibrations and mechanical stress on electronic components.

Conformal Coating does not automatically make the product suitable for use in an environment with high vibrations, but it will make the product more resilient.

4. Enhanced Electrical Insulation

These coatings can insulate traces and components on PCBs, preventing electrical shorts and improving overall safety.

What products offer the option of Conformal Coating?

All Advatek PixLite® Mk3 pixel controllers and receivers are available with the optional addition of Conformal Coating.

Similarly, PixLite® Mk 2 (Classic) PCB’s and receivers are also available with the Conformal Coating option.

Why is Conformal Coating not a standard feature on all products?

Advatek’s PixLite® Mk3 products are made to the highest standards, approved by major international certification authorities, and subject to an industry-leading 5-year warranty.

Many customer installations are indoors, where Conformal Coating is not necessary.

As a result, Conformal Coating is offered as an option for those customers who expect to use products in potentially harsh environments and wish to have added peace of mind.

How do I know if I should choose the Conformal Coating option?

For indoor installations where components are not subject to abnormal conditions, the Conformal Coating option is not typically necessary.

However, the Conformal Coating option should be considered when one or more of a range of challenging environments may be present (subject to the comments below) including:

- Outdoor installations

- Humid or high moisture indoor environments (including pools, saunas, health clubs and entertainment venues with special effects such as haze)

- Salty environments (e.g. coastal locations or installed on shipping)

- Locations with high levels of dust or other airborne pollutants

It is important to note that Advatek Products are rated for indoor use and do not become weatherproof simply by adding Conformal Coating.

They must still be installed in weatherproof housings when used outdoors.

Conformal Coating protects against airborne contaminants and moisture that may pass through weatherproof housing.

Does Conformal Coating affect Advatek’s 5-year warranty?

Advatek’s 5-year warranty on all PixLite® Mk3 products is the same whether or not the Conformal Coating option is chosen.

What does Conformal Coating not provide?

Conformal Coating provides valuable protection and enhances the durability of PCBs in adverse environments but does NOT make them waterproof or impervious to damage.

Consider Conformal Coating like adding optional paintwork protection to a new vehicle – a sensible investment that may prolong the life and quality of your paintwork if your vehicle is often parked outside, driven in harsh winter conditions, located near the sea, or subject to wind-blown dust and dirt.

Contact us for further information.

Most Popular Products

PixLite® A4-S Mk3

Driving up to 24 universes of data, and offering easy mounting, sleek design and electrical fault protection — what’s not to love?

PixLite® T8-S Mk3

With a data transmission range of 300 meters, this user-friendly long range pixel controller system is the high-impact solution for professional installations.